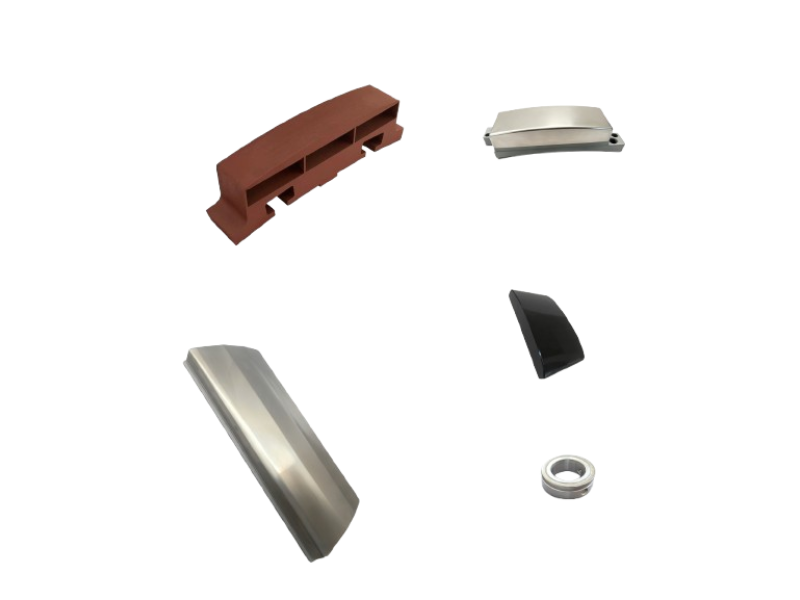

1. Magnetic feed inspections must involve random sampling of magnet dimensions and appearance. Any quality issues must be immediately reported to the wind power client’s SQE and the magnet manufacturer contacted for resolution, ensuring defective magnets are not assembled into modules.

2. During magnet unpacking, operators must conduct 100% self-inspection to ensure magnets are entirely free of surface defects.

3. Base plate incoming materials must undergo 100% dimensional and visual inspection. Cover incoming materials shall be sampled using inspection gauges simulating assembled components.

4. Base plates and covers must undergo thorough ultrasonic cleaning during the washing process. Failure to do so will compromise adhesive reliability and soldering strength. Manual cleaning is prohibited; standardised cleaning procedures must be strictly adhered to.

5. During laser marking, ensure patterns and text are clean and legible. 100% QR code verification must confirm readability, with first/last piece inspection verifying batch number uniqueness and accuracy;

6. During assembly, ensure proper alignment between the cover and base plate. The cover must be fully seated; otherwise, misalignment may occur, leading to poor soldering and height deviations.

7. For soldering, verify the soldering process validation. Confirm nitrogen flow is unobstructed, nitrogen pressure remains within process specifications, and solder joints are continuous and smooth. Solder joints must not exhibit blackening, as this indicates oxidation.

8. Upon completion of welding, process operators must conduct 100% visual inspection of weld appearance and height dimensions;

9. Products exhibiting holes during visual inspection shall be scrapped outright if hole diameter exceeds specified limits;

re-welding is permissible only for holes smaller than 1.5mm in diameter;

10. All products must undergo 100% vacuum water leak testing at <-0.05MPa pressure. If bubbles emerge from the weld periphery during water testing, the product fails airtightness; otherwise, it passes.

11. After airtightness testing, products must be blown dry with compressed air and wiped clean with a dry cloth.

12. Following airtightness testing, 100% of products must pass dimensional inspection using go/no-go gauges for length, width, and height;

13. Prior to packing, all qualified products must undergo 100% re-scanning to read each serial number and generate a packing list;

14. Each batch of shipped products must be accompanied by a dispatch report, affixed with necessary safety labels (e.g., impact-proof, waterproof), and undergo pre-dispatch inspection by quality personnel.

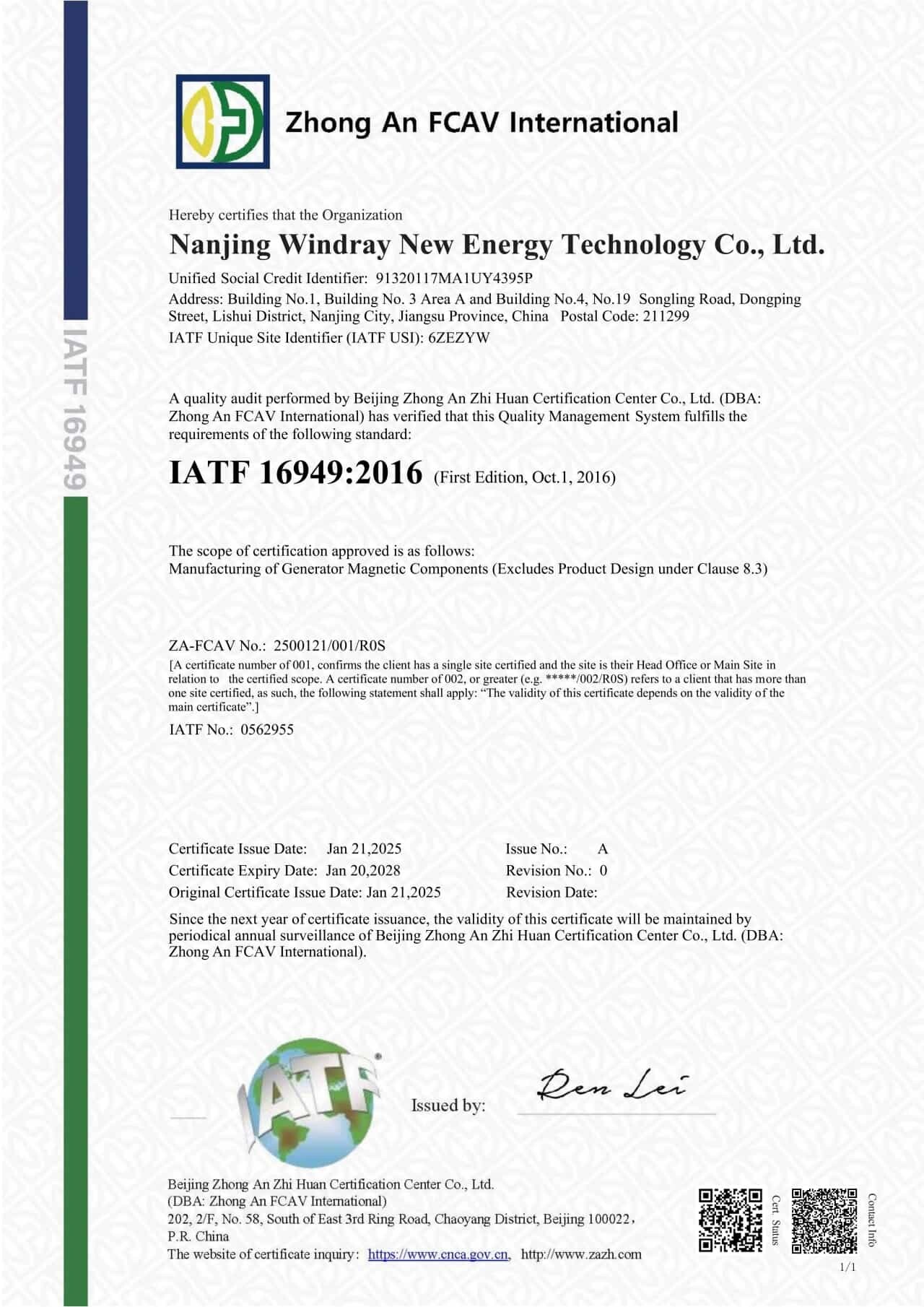

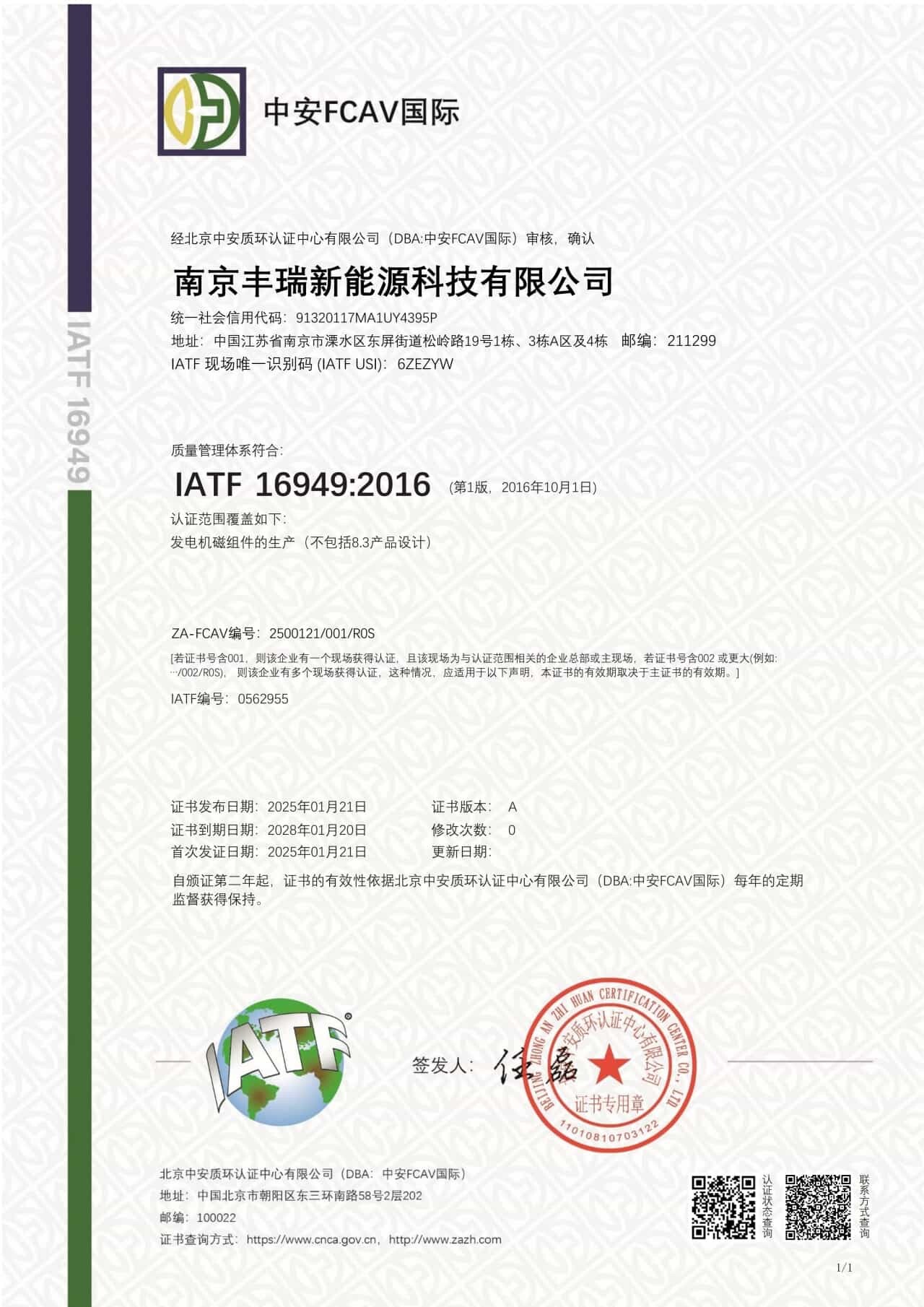

Nanjing Windray New Energy Technology Co.,Ltd